Welcome to the proposed Victorian - Wind Turbine Facility - manufacturing

| HOME | MANUFACTURING | WHY CR VAWTs | EXPERIENCE |

Manufacturing advantages:

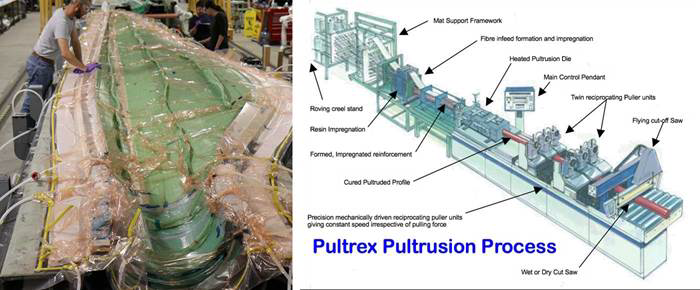

A key cost of wind turbines are

the

blades which account for 25% of HAWT costs as they are very labour intensive

(below left). Because of this complexity MOST HAWT blade failures can be traced

back to a manufacturing error.

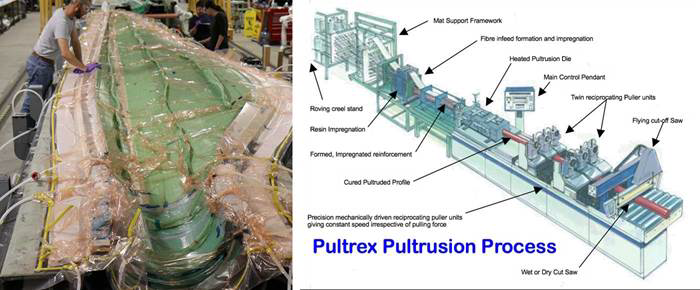

Our CR VAWT blades

are a constant NACA0018 blade profile cross section and can be manufactured

using a mechanised pultrusion process (below right) which provides industry

leading quality control with significant labour, material and time savings.

Gearboxes: Typically

represent 13% to 15% of wind turbine costs and adds complexity and maintenance

issues. The Farste Drive and CR VAWT doesn’t require any gearboxes.

| copyright VicWTF.com 2024 |